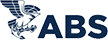

NTSKCGECWÖU CABLE STRUCTURE

| CONDUCTOR & INSULATION | |

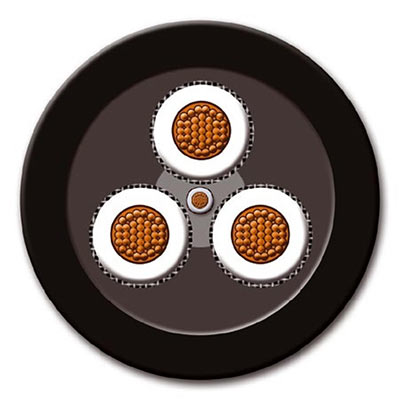

| Power Cores | |

| Conductors Insulation | Tinned copper conductor DIN VDE 0295 class 5. Based on 3GI3 – EPR rubber and semi conductive rubber compound. |

| CONTROL CORES + MONITORING PE CORE(S) | |

| Conductors Insulation | Tinned copper conductor DIN VDE 0295 class 5. 3GI3 type EPR compound and semi conductive rubber compound. |

| Cradle Separator | A shaped section of elastomeric material, semi conductive, with control wire in the center, designed to support the core assembly, fill the center interstice and provide a specified separation between individual power cores |

| Electrical Field Control | Inner and outer semiconductive layer of semiconductive rubber |

| Core Identification | Power cores naturally colored, Control cores blue colored |

| Lay Up | Three main conductors laid-up with three control cores & PE conductors in interstice over a cradle separator. |

| Inner Sheath | GM1b type EPR Compound |

| Screen / Armour | Flexible – pliable armour in helix of tinned copper and galvanised steel wires |

| Outer Sheath | 5GM5 type elastomer compound |

| Colour | Red |

NTSKCGECWÖU CABLE APPLICATION

For the connection of mobile electrical equipment in mines and tunnels. Suitable also for coal cutting machines, particularly for extreme bending loads inside of steel or plastic track chains.

NTSKCGECWÖU CABLE PRODUCTION AND TEST STANDARDS

| Construction | DIN VDE 0250-813 |

| General Requirements | DIN VDE 0250-1 |

| Guide to Use | DIN VDE 0298-3 |

| Electrical Tests | DIN VDE 0472-501, 503, 508 |

| Non-Electrical Tests | DIN VDE 0472-401, 402, 602, 303, 615 |

| Under Fire Conditions Tests | DIN VDE 0472-803, 804 |

| Flame Retardant | VDE 0482-332-1-2, DIN EN 60332-1-2, IEC 60332-1 |

| Oil Resistant | HD/EN/IEC 60811-2-1, DIN VDE 0473-811-2-1 |

NTSKCGECWÖU CABLE OPERATING CHARACTERISTICS

| Rated Voltage | 1,8/3 kV | 3,6/6 kV |

| AC Test Voltage | 6 kV | 11 kV |

| Max. Permissible | ||

| Operating Voltage AC | 2,1/3,6 kV | 4,2/7,2 kV |

| Max. Permissible | ||

| Operating Voltage DC | 2,7/5,4 kV | 5,4/10,8 kV |

| Min. Bending Radius | Acc. to DIN VDE 0298 part 3 | |

| Current Carrying Capacity | According to DIN VDE 0298, Part 4 | |

| Working Temperature | ||

| Fixed | -40ºC … +80ºC | |

| Mobile | -25ºC … +80ºC | |

| Min. Bending Radius | VDE 0298-3 Tab. 3 | |

| Current Carrying Capacities | VDE 0298-4 |

NTSKCGECWÖU CABLE SPECIFICATION

| Cross Section (mm2) | Overall Diameter Mln-Max (mm) | Conductor Resistance At 20 °C (Ω/km) | Approxlmate welght (kg/km) |

|---|---|---|---|

| 1,8/3 kV | |||

| 3 x 25 + 3 x (1,5 ST KON+ 16/3 KON) | 42.1 – 45.3 | 0.795 | 3190 |

| 3 x 35 + 3 x (1,5 ST KON+ 16/3 KON) | 46.5 – 49.7 | 0.565 | 3920 |

| 3 x 50 + 3 x (1,5 ST KON+ 25/3 KON) | 50.4 – 53.5 | 0.393 | 4730 |

| 3 x 70 + 3 x (1,5 ST KON+ 35/3 KON) | 55.8 – 60.0 | 0.277 | 6070 |

| 3 x 95 + 3 x (1,5 ST KON+ 50/3 KON) | 61.5 – 65.7 | 0.21 | 7620 |

| 3 x 120 + 3 x (1,5 ST KON+ 70/3 KON) | 66.0 – 70.3 | 0.164 | 9270 |

| 3 x 150 + 3 x (1,5 ST KON+ 70/3 KON) | 71.8 – 76.0 | 0.132 | 10920 |

| 3 x 185 + 3 x (1,5 ST KON+ 95/3 KON) | 76.2 – 80.3 | 0.108 | 12770 |

| 3 x 240 + 3 x (1,5 ST KON+ 120/3 KON) | 84.1 – 89.4 | 0.0817 | 15860 |

| 1,8/3 kV | |||

| 3 x 50 + 3 x (35 + 35/3KON) + 2 x (0,75ST KON) + 1 x (2 x 0,75 .L KON) | 66.0 – 71.0 | 0.368 | 8390 |

| 3 x 70 + 3 x (50 + 50/3KON) + 2 x (0,75ST KON) + 1 x (2 x 0,75 .L KON) | 74.0 – 79.0 | 0.272 | 10350 |

| 3 x 95 + 3 x (70 + 70/3KON) + 2 x (0,75ST KON) + 1 x (2 x 0,75 .L KON) | 85.0 – 90.0 | 0.206 | 13340 |

| 3 x 35 + 3 x (1,5 ST KON + 25/3 KON) + .L KON | 46.0 – 51.0 | 0.554 | 3960 |

| 3 x 50 + 3 x (1,5 ST KON + 25/3 KON) + .L KON | 51.0 – 55.0 | 0.368 | 4980 |

| 3 x 70 + 3 x (1,5 ST KON + 35/3 KON) + .L KON | 57.0 – 62.0 | 0.272 | 6360 |

| 3 x 95 + 3 x (1,5 ST KON + 50/3 KON) + .L KON | 64.0 – 69.0 | 0.206 | 8150 |

| 3,6/6 kV | |||

| 3 x 25 + 3 x (1,5 ST KON + 16/3 KON) | 47.3 – 50.4 | 0.795 | 3710 |

| 3 x 35 + 3 x (1,5 ST KON + 16/3 KON) | 50.2 – 53.4 | 0.565 | 4320 |

| 3 x 50 + 3 x (1,5 ST KON + 25/3 KON) | 53.5 – 57.7 | 0.393 | 5250 |

| 3 x 70 + 3 x (1,5 ST KON + 35/3 KON) | 59.6 – 63.8 | 0.277 | 6600 |

| 3 x 95 + 3 x (1,5 ST KON + 50/3 KON) | 64.3 – 68.5 | 0.21 | 8030 |

| 3 x 120 + 3 x (1,5 ST KON + 70/3 KON) | 70.7 – 74.8 | 0.164 | 9990 |

| 3 x 150 + 3 x (1,5 ST KON + 70/3 KON) | 74.5 – 78.8 | 0.132 | 11330 |

| 3 x 185 + 3 x (1,5 ST KON + 95/3 KON) | 78.5 – 83.0 | 0.108 | 13280 |

| 3 x 240 + 3 x (1,5 ST KON + 120/3 KON) | 86.8 – 92.10 | 0.0817 | 16380 |

| 3,6/6 kV | |||

| 3 x 35 + 3 x (35 + 35/3 KON) + 2 x (0,75ST KON) + 1 x (2 x 0,75.L KON) | 69.0 – 74.0 | 0.554 | 7800 |

| 3 x 50 + 3 x (50 + 50/3 KON) + 2 x (0,75ST KON) + 1 x (2 x 0,75 .L KON) | 73.0 – 78.0 | 0.368 | 9340 |

| 3 x 70 + 3 x (70 + 70/3 KON) + 2 x (0,75ST KON) + 1 x (2 x 0,75 .L KON) | 80.0 – 85.0 | 0.272 | 11580 |

| 3 x 95 + 3 x (95 + 95/3 KON) + 2 x (0,75ST KON) + 1 x (2 x 0,75 .L KON) | 89.0 – 94.0 | 0.206 | 13930 |

| 3 x 35 + 3 x (1,5 ST KON + 25/3 KON) + .L KON | 46.0 – 51.0 | 0.554 | 3960 |

| 3 x 50 + 3 x (1,5 ST KON + 25/3 KON) + .L KON | 51.0 – 55.0 | 0.368 | 4980 |

| 3 x 70 + 3 x (1,5 ST KON + 35/3 KON) + .L KON | 57.0 – 62.0 | 0.272 | 6360 |

| 3 x 95 + 3 x (1,5 ST KON + 50/3 KON) + .L KON | 64.0 – 69.0 | 0.206 | 8150 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees