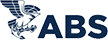

Type 440 Mining Cable Construction

| VOLTAGE | 1.1kV (Type 440.1) 3.3kV (Type 440.3) 6.6kV (Type 440.6) 11kV (Type 440.11) 22kV (Type 440.22) |

| CONDUCTOR | Tinned annealed copper wires |

| CONDUCTOR SCREEN | Paper Separator (1.1kV) Semi-conducting tape and thermosetting material (3.3kV and above) |

| INSULATION | EPR (Ethylene Propylene Rubber) type R-EP-90 |

| INSULATION SCREEN | Synthetic tape (1.1kV) Semi-conductive thermosetting compound |

| BRAID | Tinned copper/polyamide braid (3.3kV and above) |

| CABLE ASSEMBLY | Three screened power and three pilot cores laid up with right hand direction on cradle separator |

| INNER SHEATH | - |

| ARMOUR | - |

| OUTER SHEATH | Thermosetting compound HD-85-PCP - extra heavy duty, oil resistance and flame retardant |

Type 440 Mining Cable Application

Underground Mining

Type 440 cables are extensively utilized in underground mining operations, powering essential equipment such as shuttle cars that transport coal or ore from the mining face to conveyor systems, drill rigs for exploration and production drilling, and conveyor systems that move materials throughout the mine.

Open-Cut Mining

In surface mining environments, Type 440 cables supply power to massive equipment like draglines that remove overburden, mobile substations that distribute power across mining sites, and electric shovels that excavate and load materials.

Tunnel Boring Operations

During tunnel construction, Type 440 cables provide temporary power to boring machines, lighting systems, and auxiliary equipment.

Harsh Industrial Environments

Beyond mining, these cables are suitable for any industrial setting characterized by high mechanical stress, abrasive conditions, and challenging operational parameters.

Type 440 Mining Cable Characteristics

Voltage Rating

1.1kV to 22kV

Temperature Rating

-25 ℃ to +90 ℃

Type 440 Mining Cable Standards

AS/NZS 2802: 2000, AS/NZS 1125:2001, AS/NZS 2802:2003,

Water resistant and flame retardant, UV, sunlight, ozone and oil resistant

- Type 440.1 Mining Cable Specification

- Type 440.3 Mining Cable Specification

- Type 440.6 Mining Cable Specification

- Type 440.11 Mining Cable Specification

- Type 440.22 Mining Cable Specification

| NOMINAL CONDUCTOR AREA mm2 | THICKNESS OF INSULATION mm | NUMBER AND NOMINAL DIAMETER OF WIRES n x mm | NOMINAL DIAMETER OVER INSULATION mm | CORE SCREEN SIZE mm | AREA OF SCREEN mm2 | PILOT COND.STRAND/SIZE No/mm | THICKNESS EPR COVERING mm | NOMINAL THICKNESS OF SHEATH mm | NOMINAL DIAMETER mm | NOMINAL WEIGHT kg/100m |

|---|---|---|---|---|---|---|---|---|---|---|

| 6 | 1.5 | 84x0.3 | 6.5 | 7/0.25 | 7.2 | 18/0.3 | 1 | 3.8 | 30 | 135 |

| 10 | 15 | 77x0.4 | 7.7 | 7/0.25 | 8.6 | 27/0.3 | 1 | 3.8 | 32.6 | 166 |

| 16 | 1.6 | 126x0.4 | 9 | 7/0.25 | 9.6 | 42/0.3 | 1 | 4 | 35.8 | 204 |

| 25 | 1.6 | 209x0.4 | 10.5 | 7/0.25 | 11.3 | 66/0.3 | 1.2 | 4.3 | 39.7 | 269 |

| 35 | 1.6 | 285x0.4 | 12.1 | 7/0.25 | 12.4 | 90/0.3 | 1.2 | 4.6 | 43.8 | 324 |

| 50 | 1.7 | 380x0.4 | 13.8 | 7/0.25 | 14.4 | 120/0.3 | 1.2 | 5 | 48.4 | 403 |

| 70 | 1.8 | 361x0.5 | 16.1 | 7/0.25 | 16.5 | 110/0.4 | 1.2 | 5.4 | 54 | 539 |

| 95 | 2 | 475x0.5 | 17.7 | 7/0.30 | 21.8 | 110/0.4 | 1.2 | 6 | 59.4 | 659 |

| 120 | 2.1 | 608x0.5 | 20 | 7/0.30 | 24.7 | 135/0.4 | 1.4 | 6.4 | 65.2 | 802 |

| 150 | 2.3 | 740x0.5 | 22.2 | 7/0.40 | 36.9 | 152/0.4 | 1.4 | 6.9 | 72.2 | 1018 |

| 185 | 2.5 | 925x0.5 | 24.7 | 7/0.40 | 40.5 | 177/0.4 | 1.4 | 7.4 | 78.8 | 1198 |

| 240 | 2.8 | 1221x0.5 | 27.9 | 7/0.50 | 57.7 | 216/0.4 | 1.6 | 8.2 | 88.7 | 1549 |

| NOMINAL CONDUCTOR AREA mm2 | THICKNESS OF INSULATION mm | NUMBER AND NOMINAL DIAMETER OF WIRES n x mm | NOMINAL DIAMETER OVER INSULATION mm | CORE SCREEN SIZE mm | AREA OF SCREEN mm2 | PILOT COND.STRAND/SIZE No/mm | THICKNESS EPR COVERING mm | NOMINAL THICKNESS OF SHEATH mm | NOMINAL DIAMETER mm | NOMINAL WEIGHT kg/100m |

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 3 | 126x0.4 | 12.5 | 7/0.25 | 13.1 | 42/0.3 | 1.4 | 5.3 | 46.1 | 304 |

| 25 | 3 | 209x0.4 | 14 | 7/0.25 | 14.8 | 66/0.3 | 1.4 | 5.6 | 50 | 379 |

| 35 | 3 | 285x0.4 | 15.3 | 7/0.25 | 15.8 | 90/0.3 | 1.4 | 5.9 | 53.4 | 446 |

| 50 | 3 | 380x0.4 | 16.8 | 7/0.25 | 17.2 | 120/0.3 | 1.4 | 6.3 | 57.5 | 524 |

| 70 | 3 | 361x0.5 | 20 | 7/0.25 | 18.6 | 110/0.4 | 1.4 | 6.6 | 62.4 | 659 |

| 95 | 3 | 475x0.5 | 22.1 | 7/0.25 | 20.3 | 110/0.4 | 1.6 | 7.1 | 66.2 | 754 |

| 120 | 3 | 608x0.5 | 23.9 | 7/0.30 | 27.2 | 135/0.4 | 1.6 | 7.4 | 71.9 | 914 |

| 150 | 3 | 740x0.5 | 26 | 7/0.40 | 39.6 | 152/0.4 | 1.6 | 7.8 | 77.9 | 1119 |

| 185 | 3 | 925x0.5 | 28.6 | 7/0.40 | 42.2 | 177/0.4 | 1.6 | 8.2 | 83.4 | 1289 |

| 240 | 3 | 1221x0.5 | 31.2 | 7/0.40 | 46.6 | 216/0.4 | 1.6 | 8.8 | 90.2 | 1559 |

| NOMINAL CONDUCTOR AREA mm2 | THICKNESS OF INSULATION mm | NUMBER AND NOMINAL DIAMETER OF WIRES n x mm | NOMINAL DIAMETER OVER INSULATION mm | CORE SCREEN SIZE mm | AREA OF SCREEN mm2 | PILOT COND.STRAND/SIZE No/mm | THICKNESS EPR COVERING mm | NOMINAL THICKNESS OF SHEATH mm | NOMINAL DIAMETER mm | NOMINAL WEIGHT kg/100m |

|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 5 | 126x0.4 | 16.5 | 7/0.25 | 17.2 | 42/0.3 | 1.4 | 6.4 | 57.3 | 444 |

| 25 | 5 | 209x0.4 | 18 | 7/0.25 | 18.6 | 66/0.3 | 1.6 | 6.7 | 61.2 | 523 |

| 35 | 5 | 285x0.4 | 19.3 | 7/0.25 | 18.6 | 90/0.3 | 1.6 | 7 | 64.6 | 599 |

| 50 | 5 | 380x0.4 | 20.8 | 7/0.25 | 21.3 | 120/0.3 | 1.8 | 7.3 | 68.5 | 689 |

| 70 | 5 | 361x0.5 | 22.8 | 7/0.25 | 23.4 | 110/0.4 | 1.8 | 7.7 | 73.7 | 834 |

| 95 | 5 | 475x0.5 | 24 | 7/0.30 | 29.2 | 110/0.4 | 1.8 | 8.1 | 77.8 | 964 |

| 120 | 5 | 608x0.5 | 26.1 | 7/0.30 | 31.7 | 135/0.4 | 1.8 | 8.5 | 83.1 | 1119 |

| 150 | 5 | 740x0.5 | 27.9 | 7/0.40 | 45.7 | 152/0.4 | 1.8 | 8.9 | 89.1 | 1349 |

| 185 | 5 | 925x0.5 | 30 | 7/0.40 | 48.4 | 177/0.4 | 1.8 | 9.3 | 94.5 | 1529 |

| NOMINAL CONDUCTOR AREA mm2 | THICKNESS OF INSULATION mm | NUMBER AND NOMINAL DIAMETER OF WIRES n x mm | NOMINAL DIAMETER OVER INSULATION mm | CORE SCREEN SIZE mm | AREA OF SCREEN mm2 | PILOT COND.STRAND/SIZE No/mm | THICKNESS EPR COVERING mm | NOMINAL THICKNESS OF SHEATH mm | NOMINAL DIAMETER mm | NOMINAL WEIGHT kg/100m |

|---|---|---|---|---|---|---|---|---|---|---|

| 25 | 7.6 | 209x0.4 | 23.4 | 7/0.25 | 23.7 | 66/0.3 | 2 | 8.1 | 75.6 | 759 |

| 35 | 7.6 | 285x0.4 | 24.7 | 7/0.30 | 30.2 | 90/0.3 | 2 | 8.4 | 79.6 | 869 |

| 50 | 7.6 | 380x0.4 | 26.2 | 7/0.30 | 31.7 | 120/0.3 | 2 | 8.7 | 83.5 | 974 |

| 70 | 7.6 | 361x0.5 | 28.2 | 7/0.30 | 34.1 | 110/0.4 | 2 | 9.1 | 88.7 | 1139 |

| 95 | 7.6 | 475x0.5 | 29.4 | 7/0.40 | 47.5 | 110/0.4 | 2.2 | 9.6 | 93.6 | 1319 |

| 120 | 7.6 | 608x0.5 | 31.5 | 7/0.40 | 51 | 135/0.4 | 2.2 | 9.9 | 98.7 | 1489 |

| 150 | 7.6 | 740x0.5 | 33.3 | 7/0.40 | 53.7 | 152/0.4 | 2.2 | 10.3 | 103.4 | 1679 |

| NOMINAL CONDUCTOR AREA mm2 | THICKNESS OF INSULATION mm | NUMBER AND NOMINAL DIAMETER OF WIRES n x mm | NOMINAL DIAMETER OVER INSULATION mm | CORE SCREEN SIZE mm | AREA OF SCREEN mm2 | PILOT COND.STRAND/SIZE No/mm | THICKNESS EPR COVERING mm | NOMINAL THICKNESS OF SHEATH mm | NOMINAL DIAMETER mm | NOMINAL WEIGHT kg/100m |

|---|---|---|---|---|---|---|---|---|---|---|

| 35 | 10.5 | 285x04 | 32.6 | 7/0.40 | 55.4 | 90/0.3 | 2.5 | 10 | 104.9 | 1429 |

| 50 | 10.5 | 380x0.4 | 34.1 | 7/0.40 | 58.1 | 120/0.3 | 2.5 | 10.3 | 108.8 | 1549 |

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees