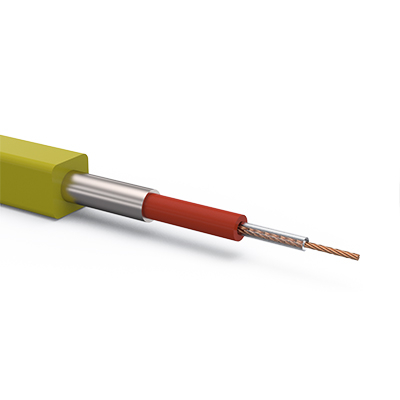

Tubing Encapsulated Cable Construction

| Conductor Layer | can be comprised of 20 AWG to 12 AWG, solid or stranded, bare copper, tinned copper, nickel plated copper, or silver plated copper. |

| Insulation Layer | can be comprised of either FEP, PFA, ETFE, or ECTFE. |

| Extruded Filler Layer | can be comprised of PFA, FEP, or Polypropylene. |

| Armor Layer | can comprised of 316L Stainless Steel, Alloy 825, or Alloy 625 |

| Final Layer | an encapsulation layer can be comprised of FEP, PFA, ETFE, ECTFE, TPV,PVDF or Polypropylene. |

Tubing Encapsulated Cable Application

Tubing Encapsulated Cable is commonly used in industries such as oil and gas production, oil well monitoring, power supply for downhole equipment and instrumentation, and pressure sensing equipment. Here are the lists.

| Category | Specific Application | Purpose of Using TEC |

|---|---|---|

| Water | Water Mains & Service Lines | Locate for repairs, avoid strikes during digging |

| Gas | Natural Gas Distribution Pipes | Critical safety: prevent ruptures and leaks |

| Wastewater | Sewer Mains & Force Mains | Locate for inspection, cleaning, repair |

| Telecom | Fiber Optic Conduit | Locate conduit path to avoid damaging critical data lines |

| Electrical | Non-Metallic Conduit | Locate to prevent electrocution hazard and outages |

| Industrial | Process & Irrigation Lines | Asset management and damage prevention on private property |

| Future Use | Conduit for New Cables | Cost-saving pathway for future utility upgrades |

| Monitoring | Leak Detection Systems | Protects and routes sensitive sensor cables |

Tubing Encapsulated Cable Feature

| Tubing options | Composed of an alloy matched to the application, then longitudinally welded, eddy current tested and drawn to finished size. |

| Electrical and Fiber Options | Temperature range, Filler, Insulation for Electrical Components, Fiber Coating, Fiber Types, Buffer Type for Optical Components. |

| Encapsulation Options | Include copper and fiber components, hydraulic control and chemical injection lines as well as mechanical components. |

Tubing Encapsulated Cable Specification

| Tubing material | Wall thickness mm [in] | Mechanical | Electrical | Cable Encapsulation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Working pressure kPa [psi] | Collapse pressure,† kPa [psi] | Tensile strength of 6.4-mm [0.25-in] tube (nominal) kPa [psi] | Yield strength of 6.4-mm [0.25-in] tube (nominal) kPa [psi] | Voltage rating V DC | Max. conductor DC resistance at 20 degC [68 degF] ohm/km | Max. conductor DC resistance at 150 degC [302 degF] ohm/km | Capacitance, center conductor to 6.4-mm [0.25-in] tube pF/m | Insulation resistance, center conductor to 6.4-mm [0.25-in] tube at 20 degC [68 degF] Mohm/km | Conductor wire gauge (AWG) | Type | Cable color | Max. working temperature, degC [degF] | Min. storage and transportation temperature, degC [degF] | ||

| 316L Stainless Steel | 0.71 [0.028] | 68,950 [10,000] | 137,900 [20,000] | 723,975 [105,000] | 655,025 [95,000] | 1,000 | 23 | 36 | 92 | 2,900 | 18 | Polyolefin | Yellow | 150 [302] | –55 [–67] |

| INCOLOY 825 | 0.89 [0.035] | 103,425 [15,000] | 206,850 [30,000] | 723,975 [105,000] | 655,025 [95,000] | 1,000 | 23 | 36 | 99 | 2,900 | 18 | Polyimide | Black | 140 [282] | –55 [–67] |

| 1.24 [0.049] | 137,900 [20,000] | 275,800 [40,000] | 723,975 [105,000] | 655,025 [95,000] | 1,000 | 23 | 36 | 114 | 2,900 | 18 | ETFE | Blue | 150 [302] | –55 [–67] | |

| 0.71 [0.028] | 68,950 [10,000] | 142,037 [20,600]† | 827,400 [120,000] | 758,450 [110,000] | 1,000 | 23 | 36 | 92 | 2,900 | 18 | FEP | Green | 175 [347] | –55 [–67] | |

| 0.89 [0.035] | 103,425 [15,000] | >204,092 [>29,600]† | 827,400 [120,000] | 758,450 [110,000] | 1,000 | 23 | 36 | 99 | 2,900 | 18 | |||||

| 1.24 [0.049] | 137,900 [20,000] | 275,800 [40,000] | 827,400 [120,000] | 758,450 [110,000] | 1,000 | 23 | 36 | 114 | 2,900 | 18 | |||||

Why Huadong Cable

Our vision is to become an internationally renowned cable brand. Customer satisfaction, employee advancement, and corporate growth are our service tenets. High standards, globalization, and building an international brand are our business philosophy.

About HuaDong

Henan Huadong Cable Co., Ltd., established in 1999, is a state-level high-tech enterprise integrating scientific research, production, and trade. Deeply engaged in the Belt and Road Initiative, Huadong Cable exports its products to over 130 countries worldwide, covering regions including Europe, South America, North America, the Middle East, Africa, Asia, and Oceania.

HuaDong Technology

HuaDong Cable focuses on technological research and development, employing 60 professionals with senior technical titles and holding over 100 invention and utility model patents. The company has assembled a team of experienced technical engineers to ensure the quality of its cable products.

Main Products

Our main products: Marine cables, power cables, overhead cables, fire-resistant cables, low-smoke zero-halogen cables, rubber cables, high-temperature resistant cables, instrumentation and control cables, solar cables, and other products.

ISO, SGS, BV CERTIFICATION; TECHNICAL PATENTS AND PRODUCT CERTIFICATION

TECHNICAL AND CLIENTS

Export Countries

Technical Patents

Annual Productivity

Employees